Do I Need To Adjust My Truck's Pinion Angle When Lowering My Truck?

Lowering your truck isn’t just about looks—it’s about performance. Whether you’re going for a clean street stance or an aggressive drop, adjusting the pinion angle is a critical step that too many guys overlook. Ignoring it can lead to nasty vibrations, premature wear on your drivetrain, and even broken U-joints. At Deviate Dezigns, we know that getting your truck dialed in the right way means making sure every component works together, and your pinion angle is no exception.

What Is Pinion Angle?

Your truck’s pinion angle is the angle of the rear differential in relation to the driveshaft. It plays a huge role in keeping your driveline operating smoothly and efficiently. Ideally, the pinion angle should be in proper alignment with the transmission output shaft to minimize stress on the U-joints and ensure smooth power delivery. When you lower your truck, that angle shifts, which can cause serious problems if not corrected.

How Lowering Affects Pinion Angle

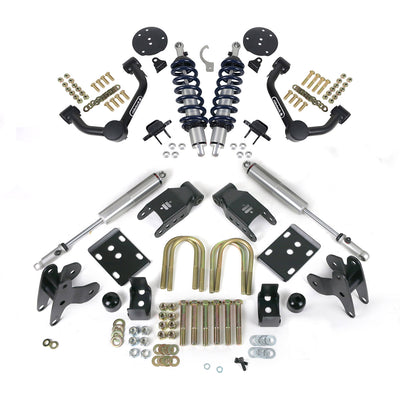

When you lower your truck, especially with drop shackles, flip kits, or coil-overs, you change the rear suspension geometry. This often tilts the differential upward or downward, throwing off the factory pinion angle. That misalignment creates excessive stress on the driveline, leading to vibration, poor acceleration, and even driveline failure over time. If you’ve ever lowered a truck and noticed a weird shudder when taking off or at highway speeds, chances are your pinion angle is out of whack.

Signs Your Pinion Angle Is Wrong After Lowering

Not sure if your pinion angle is off? Here are some telltale signs:

-

Driveline Vibration: If you’re feeling vibrations at takeoff or while cruising, your U-joints are likely under too much strain.

-

Clunking or Binding: A misaligned pinion angle can cause excessive wear on the U-joints, leading to clunking noises when shifting or accelerating.

-

Uneven Driveshaft Wear: If your driveshaft or U-joints are wearing out faster than normal, improper pinion angle could be the culprit.

-

Loss of Power: Misalignment creates resistance in the driveline, robbing you of power and efficiency.

How to Adjust Your Pinion Angle

If you’re lowering your truck, you’ll need to measure and correct the pinion angle to avoid these issues. Here’s how to get it right:

-

Measure Your Current Pinion Angle: Use an angle finder to measure the angle at both the transmission output shaft and the rear differential yoke. The goal is to have the pinion angle about 1 to 2 degrees lower than the transmission angle under load.

-

Use Pinion Angle Shims: The easiest way to correct pinion angle is by installing steel or aluminum shims between the leaf springs and the axle. These come in various degrees (e.g., 2, 4, or 6 degrees) to help fine-tune the angle.

-

Adjust Your Four-Link or Trailing Arms: If you have a four-link or trailing arm suspension setup, adjusting the length of the arms can help correct pinion angle without needing shims.

-

Recheck and Fine-Tune: After installing shims or adjusting links, re-measure the angle and test drive the truck to ensure the vibration is gone.

Final Thoughts: Get It Done Right

Lowering your truck isn’t just about dropping it and calling it a day. If you want it to perform as good as it looks, addressing your pinion angle is a must. Whether you’re running a mild drop or going all-in with a slammed setup, taking the time to correct your driveline geometry will save you from annoying vibrations and costly repairs down the road. At Deviate Dezigns, we offer the parts and expertise to help you build a truck that looks, rides, and performs the way it should. If you need help dialing in your setup, we’ve got you covered.

Leave a comment